Porn Is a Human Problem,

We Provide a Human Solution

Covenant Eyes helps you and the ones you love live porn-free through transformative accountability relationships.

Read on to learn how Covenant Eyes can work for you.

BETTER. TOGETHER.

It Starts With Relationships

A lot of companies fighting porn start with technical solutions. They believe access is the only problem. Our philosophy is different.

Friends

With Covenant Eyes, you choose someone you know and trust to walk with you as your ally and hold you accountable for your online behavior.

The Covenant Eyes app tracks activity on your devices. The Victory app shares your activity feed right to your ally’s phone.

You’ll celebrate victories together and have honest and caring conversations about your successes, setbacks, and triggers. With the Victory app, your ally will always have your back, and together, you’ll discover the freedom of living porn-free.

Couples

Has porn wounded your marriage or relationships? You aren’t alone. There are lots of people just like you who’ve felt the effects of porn on their relationships.

The good news is, there’s hope. Trust can be rebuilt and relationships restored.

With Covenant Eyes, you invite someone you know and trust to hold you accountable as your ally. For some, this is their spouse; for others, it’s someone else like a close friend or family member. The Covenant Eyes app tracks activity on your devices and offers controls to keep porn out. The Victory app shares your activity feed right to your ally’s phone.

When you invite someone to walk with you and see how you’re using your devices, it changes how you use them. These powerful tools bring honesty and transparency to your relationships, helping you rebuild trust and find healing, together.

Families

As a parent, you can be your child’s best ally on their journey to quit porn or never start using it.

The Covenant Eyes app monitors your child’s devices while our Safe Search and filtering tools keep porn at bay. The Victory app gives you a comprehensive feed of their device activity and sends you alerts if explicit material is accessed.

Together, these tools help you have honest conversations that heal shame and strengthen your relationship with your kids.

Individuals

We get that you don’t want to talk about this. It’s awkward! But isolation gives porn power.

With Covenant Eyes, you invite someone you know and trust to walk with you as your ally and hold you accountable for your online behavior. Accountability brings you out of isolation, helping you live a life of transparency and integrity by sharing your struggles with a safe and trusted friend.

The Covenant Eyes app tracks activity on your devices, and our powerful filters help keep porn at bay. The Victory app delivers a feed of your activity right to your ally’s phone, giving an objective account of your online behavior, so you can have honest and healing conversations that help you quit porn for good.

I had to learn the hard way that marriage is not a fairy tale, but I have learned that it is worth it. It’s been wonderful to watch my husband mature and grow into the man God wants him to be.

~ Covenant Eyes Member

HOW IT WORKS

2 Apps, One Simple Path to Victory

The Covenant Eyes app monitors your activity. The Victory app does everything else. It’s that simple.

Play Video to See How It Works.

Play Video to See How It Works.

Where the technology happens

Where the technology happens

Monitors and Protects

Covenant Eyes

Sensor App

The Covenant Eyes app allows you freedom through transparency. The app sits quietly on all of your devices, monitors your screen activity, and provides protection through blocking. Install this on all the devices that need to be monitored.

- Goes on all of your devices

- Uses Artificial Intelligence to scan for concerning activity

- Provides access to filtering for additional protection

Supported Platforms

Where the accountability happens

Where the accountability happens

Connects and Reflects

The Victory App

Companion App

The Victory app delivers an easy-to-use activity feed and alerts if concerning activity is detected. Specially curated courses are also available right from the app to help both you and your ally along your journey. Install this to view device activity, receive alerts, and access courses.

- Goes on all of your devices

- Uses Artificial Intelligence to scan for concerning activity

- Easy-to-Use Activity Feed

Supported Platforms

Find Victory. Try It Now.

30 Day Money-Back Guarantee

FEATURES

The Covenant Eyes Toolkit

If you want to quit porn and protect the ones you love, we’ve got the tools for you.

Monitoring

The Covenant Eyes app delivers powerful AI software that monitors your screen activity, bringing objectivity to your accountability conversations.

- Full device screen monitoring on Android tracks activity in all apps.

- In-browser screen monitoring on iOS tracks activity in Safari and the Covenant Eyes app.

- Full device screen monitoring on desktop computers.

Activity Feed

Activity is rated, then explicit and suggestive content is flagged for review on your activity feed within the Victory app.

- A scrollable, filterable feed of device activity and information is available in the Victory app.

- Our 3 class rating model uses patented AI to determine if content is explicit, suggestive, or clean.

- All content in the activity feed is blurred by design and secured with AES 256-bit encryption to protect user privacy and ally integrity.

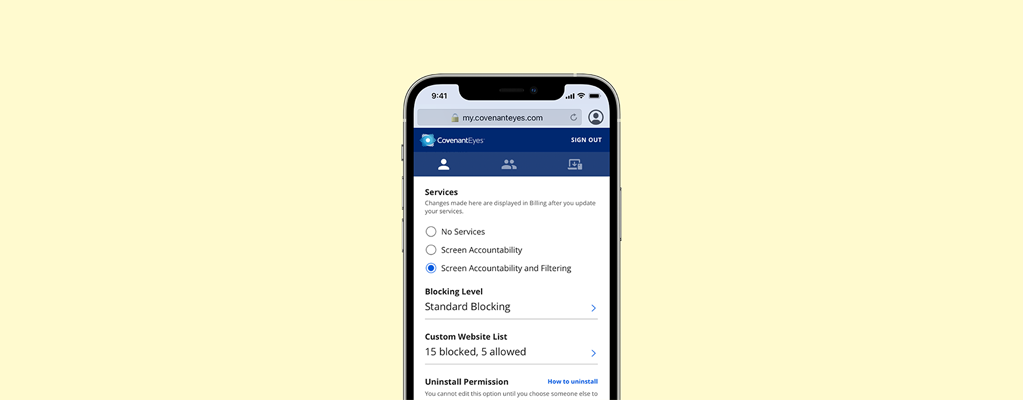

Blocking

Filtering out explicit content is an important part of preventing and overcoming porn use.

- Clean Browsing-powered domain blocking eliminates millions of explicit websites.

- Custom block and allow lists give control over what is filtered.

- Safe Search protects all major search engines and locks in YouTube Restricted Mode.

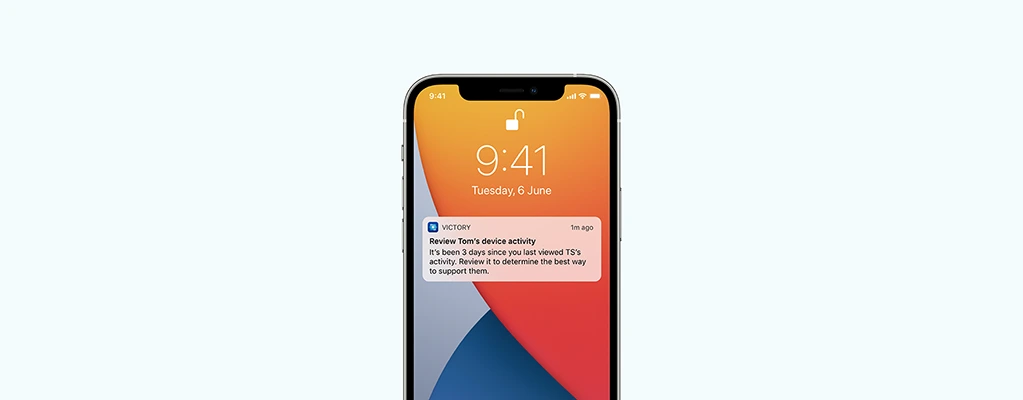

Alerts

Gain additional strength and peace of mind with check-in reminders and activity alerts.

- Activity alerts deliver quick notifications if explicit content is accessed.

- Allies can set check-in reminders.

- Peace of mind knowing if concerning activity is detected, allies will be notified.

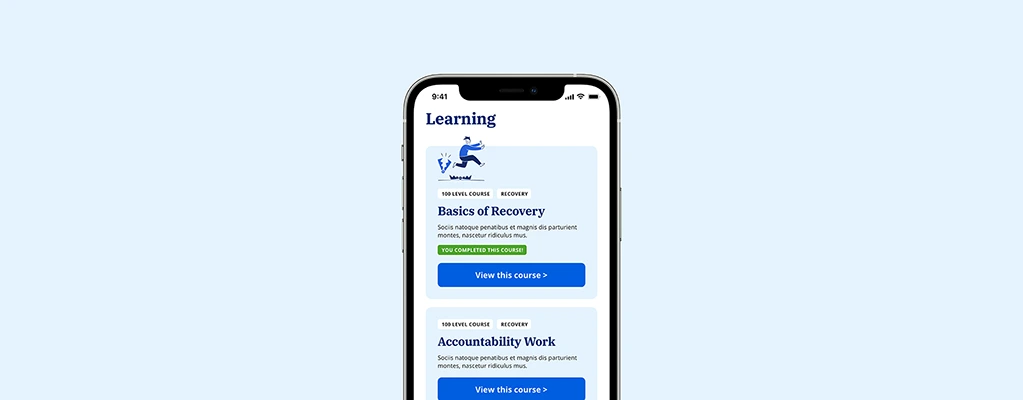

Learning

Gain access to specially created mini-courses designed to help in the journey to a life free from porn.

- Learn how porn affects our neurology and the psychology behind habitual porn use.

- Understand the power of accountability and how to support others in their journey.

- Discover other important topics that everyone needs to know in the journey to quit porn.

We Cover These Major Platforms

Whatever platform you love, we’ve got you covered.

iOS*

15.1+

MAC

10.12.1+

ANDROID

8.0+

WINDOWS

7+

Due to Apple restrictions, Screen Accountability is only available in Safari and in the Covenant Eyes app.

Screen Accountability is currently unavailable for Chromebooks, Kindle Fires, and Smart TVs.

PRICING

The Price is Right

Our pricing is simple and easy to understand. There are no complicated tiers or packages.

$17/month or $184 annually

Up to 10 users and unlimited devices

- Powerful AI Monitoring

Patented Artificial Intelligence monitors your device and scans for concerning activity. - Comprehensive Blocking

Clean Browsing eliminates millions of explicit websites and locks in YouTube restricted mode. - Multi-Class Content Rating

Our multi-class rating model uses patented AI to determine if content is explicit, suggestive, or clean.

- Easy-to-Use Activity Feed

A comprehensive feed of device activity, rated for maturity and secured with 256 bit encryption. - Notifications

Find additional strength and peace of mind with check-in reminders and activity alerts. - Exclusive Mini-Courses

Gain access to exclusive mini-courses available directly in the Victory app.